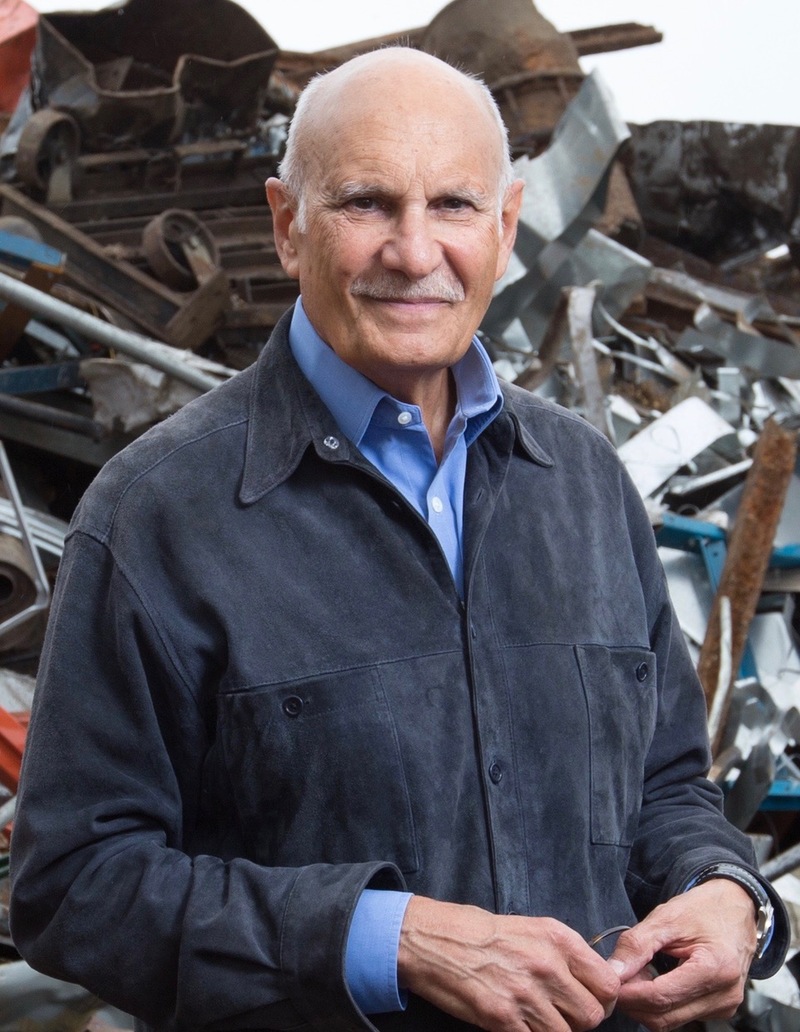

Diran Apelian Upcycles Scrap Metal for Cars and Aerospace

The Lab Beat

Oct. 28, 2025 – From developing aluminum for cars to recycling EV batteries, Diran Apelian, UC Irvine Distinguished Professor of materials science and engineering, is one of the world’s greenest and most impactful metallurgists.

In the 80s, he helped make aluminum foil stronger. In the 90s, he helped develop alloys to create the first mass-market car with an all-aluminum body, the Audi A8, paving a path for lighter, more fuel-efficient cars. As electric vehicles emerged, he found a way to recycle lithium-ion batteries, which led him to co-found the billion-dollar company Ascend Elements, named by Time magazine as one of 2024 America’s Top Ten Green Tech Companies.

“We developed the technologies to recover the cobalt, nickel and lithium, all the important elements that are near critical and reuse them into a new cathode,” Apelian said. “Ironically, the recovered material has better properties than the virgin material because we can manipulate the morphology of the powder sizes to control the conductive electronic charges.”

Apelian was inspired to become a metallurgist when he visited a U.S. Steel mill as a teenager. There he saw for the first time molten steel. “It was not a few grams, but tons of it being poured,” he recalls. “I was completely taken aback. I was fascinated. There was something magical about the smell, the visual earth and fire.” That was during the Sputnik Age when the U.S. was trying to land on the moon. “Everything in the headlines was related to material problems — the tiles protecting the vessel were falling off, etc. I put two and two together, and that’s how I got interested in metallurgical engineering.”

Now his UCI labs are using cutting-edge technology to manipulate scrap metal. “We’re developing new alloys from 100% recycled material. We’re making the sausage of metals,” he quips. His approach is ingenious and resourceful as it reduces the CO2 footprint of metal manufacturing. “When you use recycled aluminum, you save 99% of the energy,” he said. “We’re working with General Motors and some of the other companies where the materials that are being utilized in the car now is hundred percent scrap.”

The Advanced Casting Research Center (ACRC) is working with 45 global corporations to manufacture metals with enhanced properties for the aerospace and automobile industries. The lab is using new technologies such as ultrasound treatment, which can help purify metals through high frequency waves, and a million-dollar cold spray machine that 3D prints metals without melting them.

“The big advantage of cold spray is that you can make solid metal parts without melting your material, which really opens up the possibilities of using more advanced materials that melt at higher temperatures,” said doctoral student Michael Ross. “That's important for applications in extreme environments like aerospace, where they need to withstand higher temperatures.”

Apelian is also the director of the Pratt & Whitney Center which focuses on the solidification science of critical jet engine components. In an upcoming project, he aims to develop new ways to mine rare earth materials, which are critically needed in this country.

Throughout his career, Apelian and his labs have been leaving quite a legacy of greener and leaner metals for mankind to drive, fly and wander the universe in.

- Natalie Tso

(Listen to a 5-minute podcast about Diran Apelian and his UCI lab on The Lab Beat)